Excavator Hydraulic Pump Heart For John Deere's

페이지 정보

작성자 Lester 작성일 24-10-18 04:29 조회 3 댓글 0본문

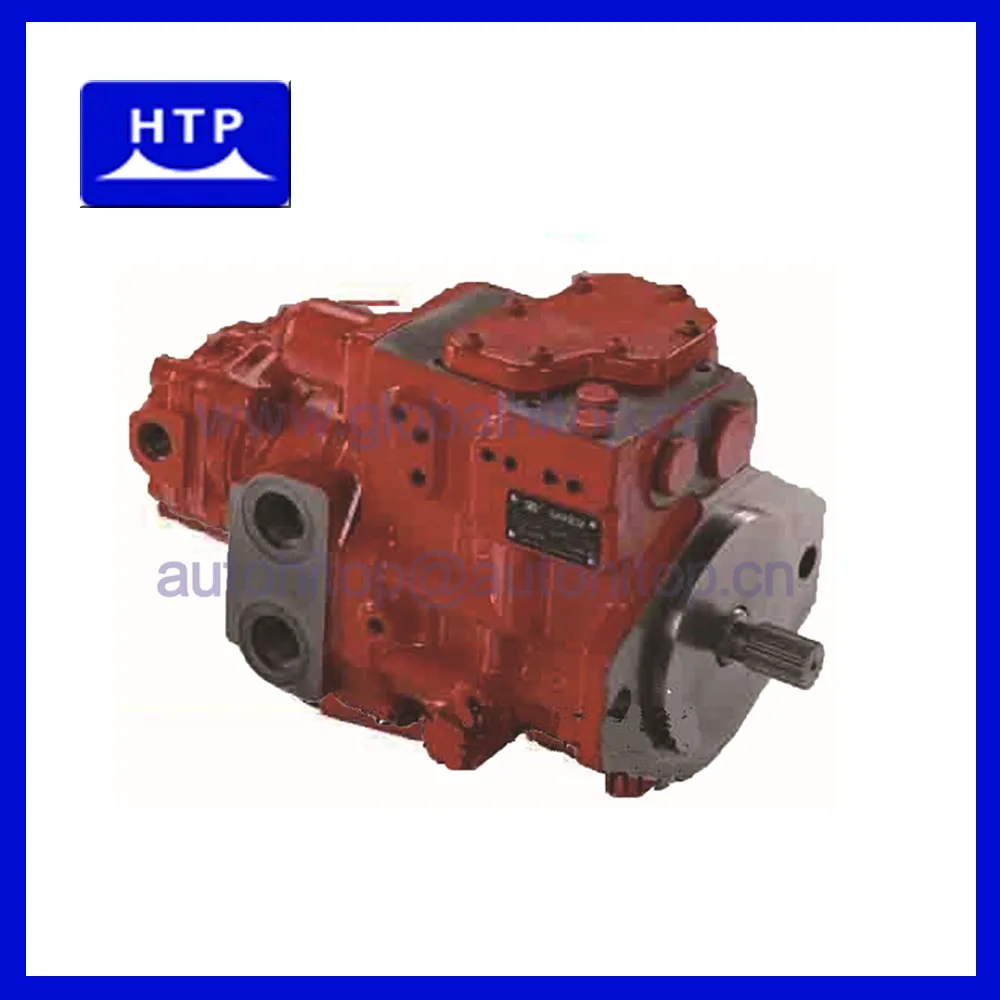

John Deere Excavator Hydraulic Pump Repair Heart and John Deere Track Hoe Hydraulic Pump Restore Heart offer John Deere excavator pumps. We additionally promote Hydraulic Parts for John Deere Excavators or John Deere Monitor Hoes. We also sell New or Remanufactured Excavator Hydraulic Pumps and all terrain crane Hydraulic Pumps for the next equipment, Doosan Excavator Hydraulic Pumps and Doosan All terrain Crane Hydraulic Pumps. Hydrostatic Transmission Service gives New or Remanufactured Excavator Hydraulic Pumps and all terrain crane hydraulic pump parts Pumps for the next equipment, Daewoo Excavator Hydraulic Pump or Daewoo All terrain Crane Hydraulic Pumps. For ten years we now have supplied New or Remanufactured Excavator Hydraulic Pumps and all terrain crane Hydraulic Pumps for the following equipment, Hitachi Excavator Hydraulic Pump or Hitachi All terrain Crane Hydraulic Pumps. When the exhaust valve opens, the vitality saved in the power converter is launched, pushing the percussion piston downwards with great pressure. Demolition hammers may be operated with totally different equipment. The most typical is a demolition spike with a tapered end, which can be utilized for general demolition work. Flat point tools with completely different leading edge lengths are a vital accessory for demolition work, but also for rock reducing and chopping duties.

What are the uses for an excavator hydraulic pump? An excavator hydraulic pump is a device that uses fluid power to create stress. The pressure created by the pump is used to move the excavator’s arm and bucket. The hydraulic pump is powered by a diesel engine. If you would like your excavator hydraulic pump to last, you need to offer it some TLC. You’ll learn the way they work as you learn this guide. 2. The place Is The Excavator Hydraulic Pump Located? You’ll discover out that different excavator makes and models have completely different designs. It can be finest to find out the location of your excavator hydraulic pump by studying the excavator’s operational manual. It’s also essential so that you can go the additional mile to learn the service handbook to learn how best you possibly can maintain your excavator hydraulic pump.

These fashions additionally function clean firing protection, decreasing the danger of damage to the breaker and wear to the service machine. The FX-Pro sequence of hydraulic breakers from Hydraram combines design features developed by means of its CAD/CAM services with particular alloy steel mixtures and, says the corporate, years of user field expertise. The best share of the Europe market is attributed to increasing demand for hydraulic breakers in construction applications. The hydraulic breaker is a piece of development equipment that is used to deconstruct buildings and scale back the scale of rocks. It is an excavator attachment that operates on a hydraulics basis. These tools are continuously used within the mining and construction industries to extend production and cut back labor prices. The event in infrastructure and construction initiatives in developed international locations is one in every of the key components influencing the growth of the worldwide hydraulic breaker market.

By contemplating the above factors, you possibly can ensure that you buy the right hydraulic pump coupling to your excavator, which is able to work effectively and effectively for a long time. The hydraulic pump coupling on an excavator is a device that connects the engine’s rotational movement to the pump. Its function is to provide a mechanical connection that can transmit energy between the engine and the pump, allowing the excavator’s hydraulic system to operate properly. This coupling permits the hydraulic pump to attract in hydraulic fluid from the reservoir and generate the necessary stress for operating the assorted hydraulic features of the excavator. Bleeding the air from the system, cleaning or replacing the valves, or servicing the cylinders could also be required to resolve the difficulty. 1. Overheating: Extreme heat buildup in the hydraulic system will be caused by a malfunctioning cooling system, inadequate fluid levels, or excessive load on the excavator. Addressing the foundation trigger, similar to repairing the cooling system or adjusting the load, is essential to forestall additional harm. 1. Contamination: Dirt, debris, or other contaminants within the hydraulic fluid could cause wear and harm to the system’s elements. Regular fluid modifications and filtration upkeep are important to prevent contamination-associated issues. 1. Hydraulic cylinder failure: Cylinder issues, equivalent to leaks, binding, or reduced stroke, might be attributable to worn seals, damaged rods, or inner element failure. Changing the affected cylinder or rebuilding it could also be vital to revive correct operate.

- 이전글 Five Things Everyone Makes Up About Coffee Machine For Beans

- 다음글 I do not Wish To Spend This Much Time On Online Tennis Betting Site. How About You?

댓글목록 0

등록된 댓글이 없습니다.